Anderson

Selexx CNC Nesting Machine

At Total Panel Products, we utilize the Anderson CNC Nester for high-precision wood, MDF, melamine, and composite processing. This advanced machine is designed for high-speed, accurate panel cutting, ensuring minimal material waste and maximum efficiency in production.

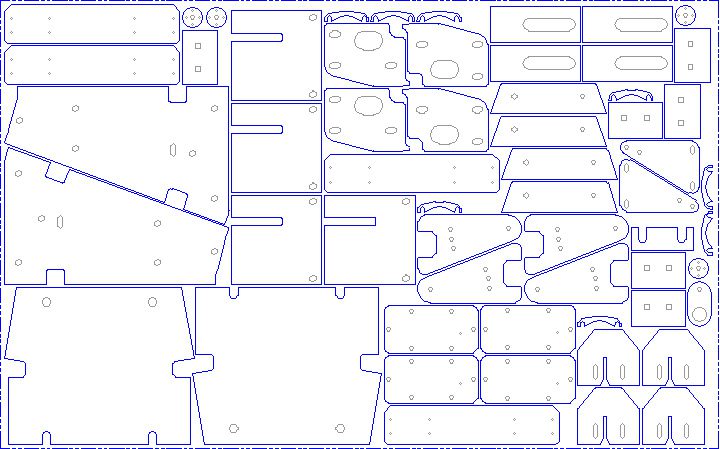

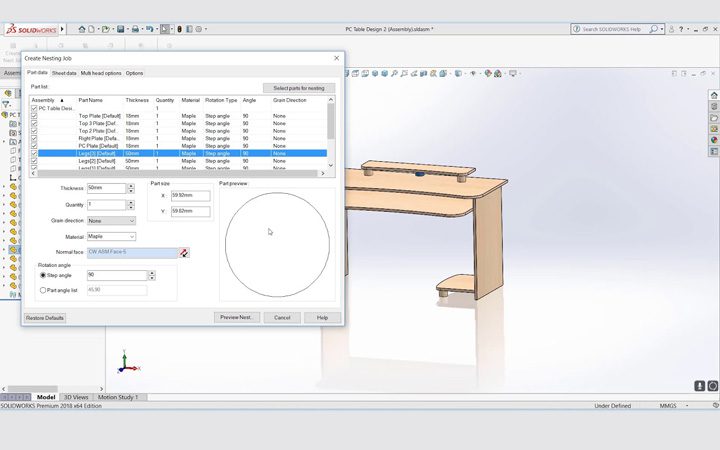

What is Nesting?

CNC nesting is a smart manufacturing process that optimizes material usage by arranging cut patterns efficiently before machining. The Anderson CNC Nester takes these layouts and automatically cuts panels with extreme precision, reducing errors and improving production speed.

Anderson CNC Nester – Key Features & Benefits:

✔ High-speed processing for mass production & custom projects

✔ Precision cutting with advanced nesting software

✔ Efficient material usage to minimize waste & costs

✔ Versatile material handling – works with wood, MDF, melamine, & composites

✔ Consistent accuracy for repeatable high-quality results

Anderson CNC Nester – Key Features & Benefits:

✔ High-speed processing for mass production & custom projects

✔ Precision cutting with advanced nesting software

✔ Efficient material usage to minimize waste & costs

✔ Versatile material handling – works with wood, MDF, melamine, & composites

✔ Consistent accuracy for repeatable high-quality results

Advanced CNC Machining for Furniture & Panel Production

Our Anderson CNC Nester allows us to manufacture bespoke furniture components, panel products, and custom woodwork for industries like:

✔ Furniture Manufacturing – Cutting & shaping wood panels for furniture components

✔ Retail & Commercial Fixtures – Display units, shelving, & shop fittings

✔ Office & Contract Furniture – Worktops, desks, and storage units

✔ Education & Healthcare – Custom furniture for schools & medical facilities

With its automated layout execution, the Anderson CNC ensures every panel is cut accurately, whether you're producing one-off custom pieces or large-scale batches.

For high-quality CNC nesting services with the Anderson CNC Nester, contact us today! Our team will help you achieve precise, efficient, and cost-effective panel production.

✔ Furniture Manufacturing – Cutting & shaping wood panels for furniture components

✔ Retail & Commercial Fixtures – Display units, shelving, & shop fittings

✔ Office & Contract Furniture – Worktops, desks, and storage units

✔ Education & Healthcare – Custom furniture for schools & medical facilities

With its automated layout execution, the Anderson CNC ensures every panel is cut accurately, whether you're producing one-off custom pieces or large-scale batches.

For high-quality CNC nesting services with the Anderson CNC Nester, contact us today! Our team will help you achieve precise, efficient, and cost-effective panel production.

Anderson Nesting Images

Take a look at our Anderson nesting related images:

Opening Hours

Mon - Thu: 8am - 5pm

Fri: 8am - 4pm

Fri: 8am - 4pm

Contact Us

Total Panel Products Ltd

Liverpool Office,

Unit 6 , Luton Street,

Liverpool, Merseyside,

L59XR

Liverpool Office,

Unit 6 , Luton Street,

Liverpool, Merseyside,

L59XR

Registration Details

Company registration: 06246602

Vat registration number: 193816477

Vat registration number: 193816477

Copyright © 2015-2018 Total Panel Products