At Total Panel Products, we deliver high-quality panel processing solutions for the furniture industry UK. With decades of expertise, cutting-edge CNC machinery, and advanced software solutions, we provide cost-effective, optimized wood cutting services, plus edging and drilling, for design, planning, and production. From school, office, and hospital furniture to acoustic panels, lockers, worktops, and bespoke contract furniture, we cater to diverse needs.

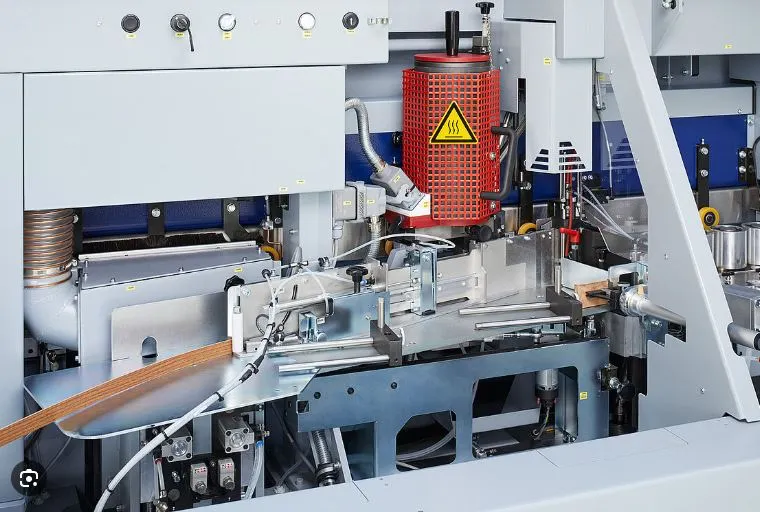

Our state-of-the-art technology—working with laminate, MFC, MDF, wood, and plastics—ensures precision in cutting, shaping, drilling, edging, bonding, and postforming. Whether using your materials or ours, we maximize efficiency and material usage while minimizing machining time. Our latest-generation CAD/CAM software accepts most formats, seamlessly converting your drawings from screen to machine with reduced processing times.....